The Role of Netting Debris in Construction Fall Protection Systems

Construction safety nets serve as critical safeguards against falls, but their effectiveness depends on proactive debris management. Industry data shows debris-laden nets lose up to 40% of their shock-absorbing capacity, compromising worker protection.

How Netting Debris Compromises the Performance of Personnel Fall Safety Nets

Accumulated debris weakens safety nets through three mechanisms:

- Added Mass – Every 2.2 lbs (1 kg) of debris triples downward force during fall arrests due to velocity

- Material Fatigue – Sharp debris accelerates UV degradation and fiber breakage

- Hydrostatic Locking – Waterlogged debris reduces energy absorption by 30-50%

| Net Condition | Max Arrest Force | Debris Capacity | OSHA Compliance |

|---|---|---|---|

| Clean | 22 kN | 0 kg | Yes |

| Debris-Loaded | 14 kN | 4 kg | No |

This silent degradation creates false security – nets appear intact while harboring failure risks.

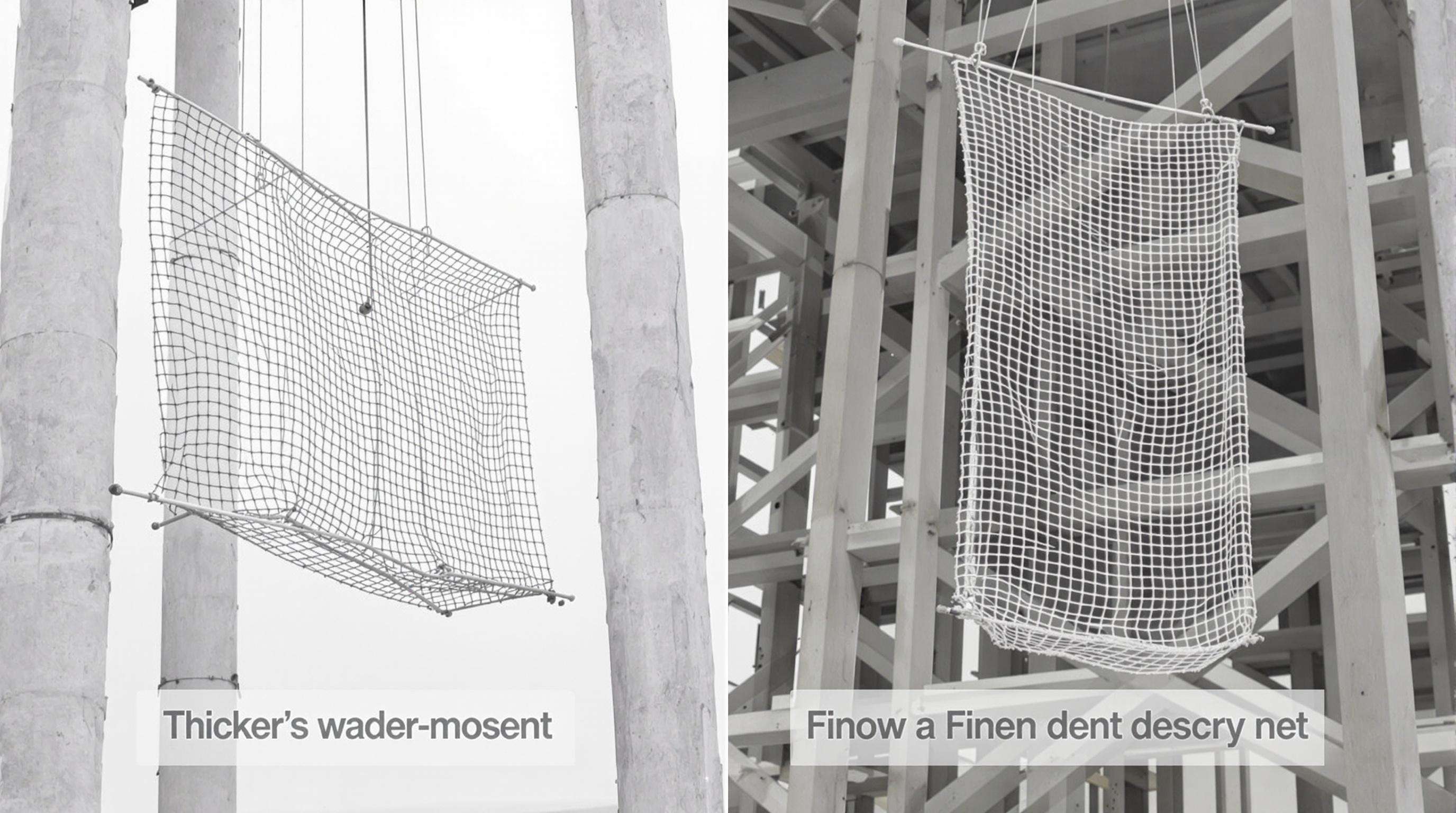

Key Differences Between Personnel and Debris Containment Nets

These systems have distinct purposes:

- Mesh Density: ‰6" openings for personnel vs. ‰1" for debris nets

- Load Paths: 4+ anchor points for personnel vs. 2-point debris net anchoring

- Materials: ASTM F2953 polyester for personnel vs. polypropylene for debris

Using debris nets for fall protection violates OSHA 1926.502(c) due to inadequate energy absorption.

Why Managing Netting Debris Is Critical

Daily debris removal preserves two vital functions:

- Structural Capacity – Ensures proper energy dissipation during falls

- Visibility – Allows unobstructed inspection for damage

A 2022 Chicago high-rise incident demonstrated cascading failures where debris accumulation led to undetected corrosion and partial net collapse.

Common Causes of Netting Debris Accumulation

Construction Material and Tool Fragments

Material spillage generates 62% of worksite debris (BLS 2023). Unsecured tools and loose materials often migrate into nets through edge protection gaps.

Environmental Factors

Wind disperses debris while rain deposits sediment. OSHA found weather events contributed to 28% of coastal debris incidents. Ice accumulation can increase net loads by 300% in winter.

Poor Site Management

Sites lacking debris protocols experience 4x faster net degradation. Common oversights include:

- Overflowing trash bins near nets

- Missing secondary catch platforms

- Oversized mesh allowing particle buildup

41% of contractors lack written debris plans, despite nets with >5 lbs/sq ft debris having 73% higher failure rates.

Safety and Structural Risks of Unmanaged Netting Debris

Reduced Load Capacity

Debris ‰¥75 lbs (34 kg) reduces net capacity by 40% (ASTM 2023), accelerating UV degradation and weakening critical stress points.

Combined Load Dangers

900 lbs (408 kg) of debris lowers safety margins by 52% for personnel falls (NIST 2019), prompting ANSI/ASSP A10.11-2023 to mandate 24-hour debris removal.

Chicago High-Rise Case Study

A Chicago project halted when 1.8 tons of debris stretched nets beyond limits, resulting in $134k OSHA violations for overloading and inadequate inspections.

Secondary Hazards

Debris creates:

- Laceration risks from sharp objects

- Snag points for fall equipment

- Unpredictable net deflection

23% of fall protection violations involve compromised nets, with debris-related failures accounting for 17% of construction falls (2019-2022).

Best Practices for Safety Net Maintenance

Inspection Routines

Conduct pre-shift checks for:

- Material accumulation

- UV degradation signs

- Rust/corrosion at attachment points

Daily inspections reduce material failures by 63% compared to weekly checks.

| Inspection Area | Critical Checkpoints | Action Threshold |

|---|---|---|

| Mesh Integrity | Tears >6" long | Immediate replacement |

| Border Ropes | Abrasions exposing >10% of fibers | Reinforcement required |

| Debris Load | >5 lbs/sq ft | Clean within 4 hours |

Cleaning Procedures

- Deactivate fall zones during cleaning

- Use soft brushes to dislodge debris upward

- Store debris in sealed containers

- Verify <2% elongation post-cleaning

Avoid pressure washing – it accelerates fiber breakdown.

Storage Guidelines

- Hang vertically in shade for ‰48 hours to dry

- Fold along manufacturer creases with acid-free tissue between layers

- Climate-controlled storage (50-70°F, 40-60% humidity) preserves 92% of tensile strength after 5 years

OSHA Compliance

Mandates include:

- Weekly certified inspections

- Immediate removal of unmaintained nets

- 180-day load testing with 400-lb sandbags

- Full debris clearance before relocating nets

Maintain inspection records for 3+ years.

Innovations in Debris-Resistant Safety Nets

New technologies focus on:

- UHMWPE polymers offering 60% higher abrasion resistance

- Hexagonal weaves reducing wind-driven debris by 35%

- IoT-enabled nets monitoring real-time debris loads

- Nanofiber coatings showing 40% less debris adhesion

These advancements align with evolving OSHA priorities for proactive debris management.

FAQ

What are the main causes of netting debris accumulation?

Debris accumulation is primarily caused by construction material and tool fragments, environmental factors such as wind and rain, and poor site management practices, including inadequate debris protocols.

Why is debris removal from safety nets crucial?

Debris removal is essential to maintain the structural capacity and visibility of the nets, ensuring they function correctly during falls and allowing for effective inspections to prevent failures.

What are the consequences of unmanaged netting debris?

Unmanaged debris can severely reduce a net's load capacity and safety margins, introduce secondary hazards, and lead to potential OSHA violations due to compromised safety standards.

Are debris containment nets suitable for fall protection?

No, using debris nets for fall protection violates OSHA regulations due to their inadequate energy absorption capabilities compared to personnel safety nets.

What are some innovations in debris-resistant safety nets?

Advancements include UHMWPE polymers, hexagonal weaves, IoT-enabled nets, and nanofiber coatings, all of which improve debris resistance and align with OSHA's evolving priorities.

Table of Contents

- The Role of Netting Debris in Construction Fall Protection Systems

- How Netting Debris Compromises the Performance of Personnel Fall Safety Nets

- Key Differences Between Personnel and Debris Containment Nets

- Why Managing Netting Debris Is Critical

- Common Causes of Netting Debris Accumulation

- Safety and Structural Risks of Unmanaged Netting Debris

- Best Practices for Safety Net Maintenance

- Inspection Routines

- Cleaning Procedures

- Storage Guidelines

- OSHA Compliance

- Innovations in Debris-Resistant Safety Nets

- FAQ