Vinyl Tarp Durability: Strength, Weather Resistance, and Lifespan

Material Composition and Performance of Vinyl Tarps

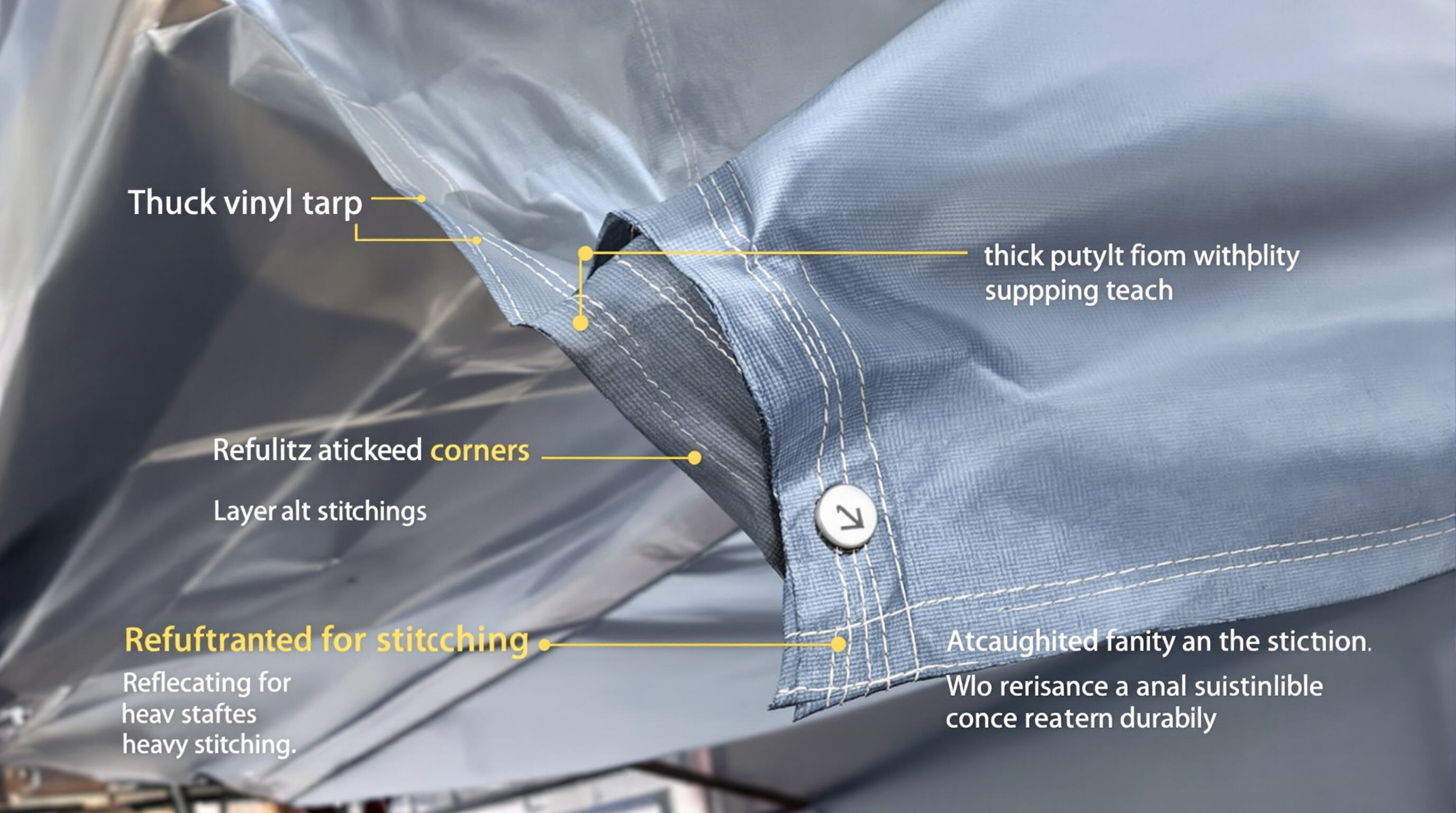

Vinyl tarps are made using layers of polyvinyl chloride or PVC, usually between 10 and 40 mils thick. Thicker versions tend to hold up better against punctures and wear and tear over time. Most quality vinyl tarps have a woven polyester backing that adds strength, and many come with steel reinforced corners and extra strong stitching along the edges. This construction allows them to handle around three to five times more stress compared to regular plastic tarps. They stay intact even when exposed to harsh stuff like oil spills or acidic substances, and they work reliably across a wide temperature range from as cold as minus 40 degrees Fahrenheit all the way up to 180 degrees. Because of these properties, workers in manufacturing plants, warehouses, and construction sites often prefer vinyl tarps whenever they need something that won't break down chemically or let water through.

Tear, Puncture, and Abrasion Resistance in High-Stress Conditions

The layered PVC construction of vinyl tarps delivers exceptional performance under stress. Independent testing demonstrates significantly higher resistance compared to poly tarps:

| Test Metric | Vinyl Tarp Performance | Industry Standard (Poly Tarps) |

|---|---|---|

| Puncture Resistance | 150+ lbs | 40–60 lbs |

| Abrasion Cycles (ASTM) | 15,000+ | 3,000–5,000 |

| Tear Strength (lbs/ft²) | 220 | 80 |

Field data from 2023 shows less than 5% failure rates in demanding conditions involving heavy machinery, sharp debris, or wind speeds over 50 mph, confirming their reliability in high-risk applications.

UV and Weather Resistance in Extreme Climates

Vinyl tarps with those fancy UV inhibitors last way longer than regular polyethylene ones. We're talking about cutting down on degradation by somewhere around 80 to 90 percent, which means these tarps can hang out outside for 5 to maybe 10 years if someone actually takes care of them properly. What's really impressive is how they stand up against mildew, cracks, and fading even after spending over 2000 hours under direct sunlight. That kind of exposure would translate to roughly 3 to 4 years worth of beating from the sun in places like Florida or Texas. Tests show these materials stay stable across a pretty wide temperature range too, from super cold at minus 40 degrees all the way up to 180 degrees Fahrenheit without getting brittle or warped. Regular plastic tarps usually start falling apart within just 1 to 3 years when subjected to similar treatment.

Poly Tarp Durability: Performance and Limitations in Outdoor Use

Material Structure and Strength of Poly Tarps

Poly tarps are basically made from woven synthetic fibers that get coated with liquid polyethylene to make them waterproof. They come in different thickness levels ranging from about 5 mils for light duty stuff all the way up to 20 mils for heavy duty applications. These tarps can hold up against moderate winds pretty well and since they're so light weight, installation isn't too difficult either. The downside though is that compared to industrial grade materials, regular poly tarps don't have much structural reinforcement built into them. For things like covering garden tools during winter months, the lighter versions between 5 and 9 mils usually do the job just fine. But when dealing with harsher conditions over longer periods, going for the heavier options from 10 to 20 mils makes more sense as they can handle extended weather beating much better.

Tear and UV Resistance Compared to Reinforced Alternatives

UV inhibitor coatings do make these materials last longer, but after sitting out in the sun for around two to three years, polyethylene starts breaking down. For regular everyday stuff, poly tarps work okay, though they tend to tear easily when something sharp goes through them. They just don't hold up as well against punctures compared to stronger options like vinyl, particularly during those windy days when the tarp keeps flapping around and wearing itself out faster. As months pass by, all those plasticizers inside start evaporating away, making the material brittle over time. Even if there's some kind of protective coating on it, the water resistance gets worse until eventually, rainwater finds its way through.

Expected Lifespan Under Continuous Outdoor Exposure

Industry data indicates poly tarps last 1–3 years under continuous outdoor use, significantly less than reinforced options. Key factors driving degradation include:

- UV radiation: Causes fading and embrittlement despite stabilizers

- Temperature extremes: Repeated expansion and contraction weaken fibers

- Physical stresses: Wind flapping and surface abrasion compromise integrity

With proper handling, lifespan can be maximized, but most residential-grade poly tarps require replacement within 24 months of constant deployment. This makes them cost-effective for temporary needs rather than permanent protection.

Direct Comparison: Vinyl vs. Poly Tarps in Real-World Applications

Strength, Flexibility, and Performance in High-Stress Environments

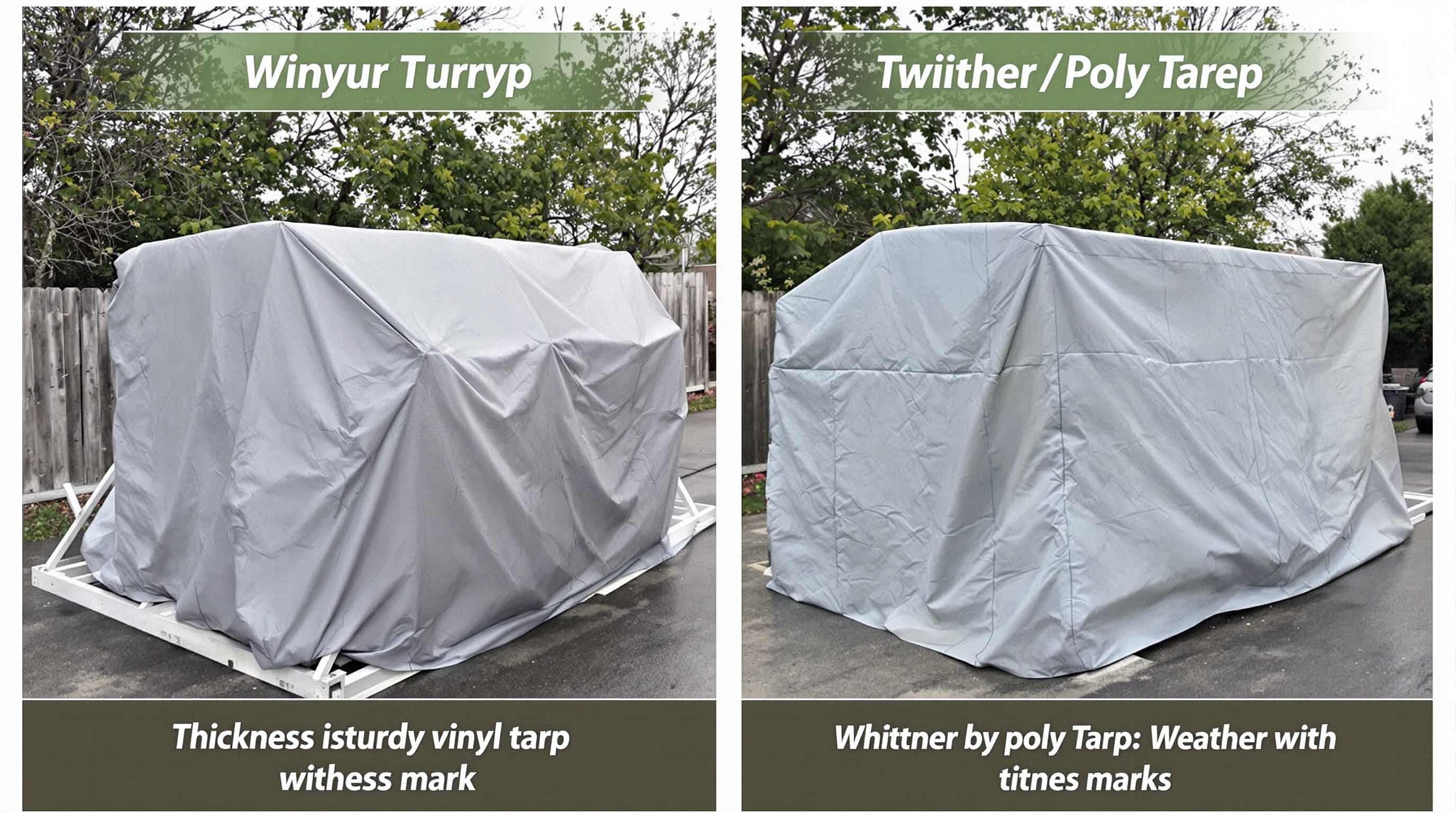

When it comes to tough jobs, vinyl tarps beat out their poly counterparts hands down. The extra reinforcement in the fabric plus those sealed seams really hold up when things get tense around sharp corners or during strong winds that can exceed 50 miles per hour without tearing apart. Poly options might be easier to handle because they're lighter weight and bend better, but they just don't stand up to rough treatment as well. They tend to show wear faster and tear easily if something sharp catches them. That's why contractors who need protection for expensive machinery on site often go with vinyl. These heavy duty covers keep working even after months of exposure to harsh weather conditions, so there's less chance of losing gear to unexpected failures during important projects.

Cost vs. Longevity: When Vinyl Outperforms Poly Tarps

Poly tarps might seem cheaper at first glance, saving around 40 to 60 percent on the initial purchase price, but vinyl actually proves more valuable over time when used outdoors for extended periods. Vinyl products treated with UV protection can stick around for five to eight years or even longer, whereas poly tarps usually start breaking down after just one to three seasons, which means replacing them again and again. For folks looking to protect expensive stuff like farm equipment or large quantities of stored goods, those extra few years of service from vinyl definitely justify paying more initially. Most contractors who need something reliable for several years end up going with vinyl because they know what happens when cheap alternatives fail during critical moments.

Use Case Scenarios: Choosing Between Vinyl and Poly Based on Durability Needs

| Scenario | Vinyl Tarp Recommendation | Poly Tarp Recommendation |

|---|---|---|

| Long-term equipment shelter | “ Optimal (UV/mold resistance) | “ Unsuitable |

| Event tenting (3-day use) | “ Over-specified | “ Optimal (UV/mold resistance) |

| Chemical exposure zones | “ Optimal (UV/mold resistance) | “ Unsuitable |

| Emergency storm covers | “ Optimal (UV/mold resistance) | “ Marginal (short-term) |

For areas that face extreme temperatures ranging from -40 degrees Fahrenheit all the way up to 180 degrees, or places where chemicals might be present, vinyl tends to be the better choice for long term installation needs. On the flip side, poly works fine enough for lighter duty stuff like those temporary garden coverings we put up seasonally when it makes sense to replace them every now and then. When looking at what can hold weight, there's quite a difference between these materials. Vinyl generally handles snow loads around 25 pounds per square foot, while poly only manages about 10 to 15 pounds before showing signs of stress. That makes a big difference when considering durability over time especially during winter months.

Environmental Impact on Tarp Longevity and Material Degradation

Effects of Sun, Cold, and Moisture on Vinyl and Poly Tarps

Vinyl tarps stand up much better against UV rays than most alternatives, so they keep their strength even after sitting out in the sun for months at a time. The same can’t be said for unstabilized poly tarps which tend to break down around 40 percent quicker each year when exposed to similar sunlight levels. When temps drop below minus 20 degrees Fahrenheit, vinyl stays pliable enough to handle normal handling, but unstabilized poly gets really stiff and starts cracking easily if moved around too much. Water behavior is another big difference worth noting. Vinyl is completely waterproof from the inside out, stopping mold growth dead in its tracks. Poly tarps however often trap water between layers, creating a breeding ground for microbes unless specially coated with something that allows vapor to escape through the material.

Sustainability and End-of-Life Considerations for Both Materials

The recycling story varies quite a bit between these materials actually. Poly tarps tend to get recycled more often because there are already good polyethylene recovery systems in place. But PVC based vinyl tarps run into problems when it comes to recycling thanks to their chlorine content plus all the extra steps needed for separation. If either type ends up just sitting around instead of being disposed of properly, we're talking about decomposition times stretching well beyond a century. On the flip side though, vinyl does last much longer before needing replacement which helps balance out some of those recycling issues. Still, nobody can ignore how important proper end of life management really is here. Industry data reveals something pretty shocking too - more than seventy percent of old poly tarps still wind up in landfills even though they could technically be recycled. That kind of waste just doesn't sit right with most people these days.

FAQ

What is the main advantage of vinyl tarps over poly tarps?

Vinyl tarps offer superior strength, weather resistance, and chemical resistance. They last longer than poly tarps, making them ideal for long-term outdoor use, especially in harsh environments.

How long do vinyl tarps typically last?

With proper care, vinyl tarps can last between 5 to 10 years, thanks to their UV inhibitors that greatly reduce degradation.

Are poly tarps suitable for heavy-duty applications?

Poly tarps are generally not recommended for heavy-duty applications as they lack the structural reinforcement that vinyl tarps provide, making them more prone to tearing and UV damage.

What factors contribute to the degradation of poly tarps?

Factors like UV radiation, temperature extremes, and physical stresses such as wind and abrasion contribute to the lower lifespan of poly tarps.