Why Hay Covers Are Essential for Preserving Forage Quality

Understanding the Role of Hay Cover in Preserving Forage Quality

A good cover over hay makes all the difference when it comes to keeping forage from going bad. Left unprotected, hay tends to lose between 15 and 35 percent of its dry matter every year because of rain, snow falling on it, and those harsh UV rays from the sun according to some research from Ponemon back in 2023. Quality covers help keep the crude protein intact and stop the cellulose from breaking down so fast. This means better nutrition stays in the feed which is what animals need for proper growth and good milk output. Farmers who want their livestock thriving know this stuff matters a lot.

How Moisture and Humidity Compromise Unprotected Hay

Rainfall penetrates uncovered hay within 48 hours, creating conditions conducive to microbial growth. When humidity exceeds 65%, thermophilic bacteria become active, raising internal bale temperatures above 130°F and accelerating decomposition. This damp environment also leaches water-soluble nutrients like sugars and potassium, reducing total digestible nutrients (TDN) by up to 28%.

Data on Average Dry Matter Loss in Uncovered Hay Stacks

When left uncovered, hay tends to lose around 22% of its dry matter each year, while covered stacks only see about 6% loss. That adds up fast for mid sized operations, with some farms losing anywhere from $740 to over $1,200 per acre just on wasted feed alone. Research indicates that when hay sits out in the open, the neutral detergent fiber content goes up by roughly 11%, making it less appealing to livestock and reducing how much they actually eat. Most of these losses come down to microbial activity, which accounts for about 85% of the total degradation. Fortunately there's a solution. Using breathable yet waterproof covers can stop this process dead in its tracks by keeping moisture levels right around that sweet spot of 12 to 15 percent, which is exactly what farmers need to preserve quality without creating mold issues.

Comparing Hay Cover Materials: Tarp, Plastic, and Canvas Options

Polyethylene tarps for cost-effective outdoor hay storage

Polyethylene tarps offer an affordable solution for short-term hay protection, featuring water-resistant coatings and woven layers that shed moisture. While effective initially, they degrade under prolonged UV exposure, becoming brittle and prone to tearing—limiting their lifespan in sunny or high-wind environments.

UV-resistant plastic covers and their durability in sunlight

UV-stabilized plastic covers contain light-resistant additives that extend service life by 40–50% compared to standard polyethylene. Their reflective surfaces help regulate internal temperatures, which is especially beneficial in subtropical regions where thermal stress accelerates hay degradation by up to 24%.

Breathable canvas covers and their role in ventilation needs

Treated woven canvas allows controlled air exchange through micro-porous fibers, enabling humidity to escape while blocking rain. This breathability prevents condensation buildup that leads to mold—common under non-porous covers. Canvas performs best when humidity stays below 60%, preserving forage integrity over extended storage periods.

Comparative lifespan and tear resistance across materials

| Material | Lifespan (years) | Tear Resistance | UV Degradation Rate |

|---|---|---|---|

| Polyethylene | 2-3 | Moderate | High |

| UV-stabilized | 4-5 | High | Low |

| Canvas (treated) | 5+ | Moderate-High | Moderate |

Canvas offers the longest service life with proper care, while UV-stabilized plastics provide a balanced mix of durability and cost efficiency. The best material choice depends on climate conditions and budget priorities.

Key Features of High-Performance Hay Covers: Waterproof, UV-Resistant, and Breathable

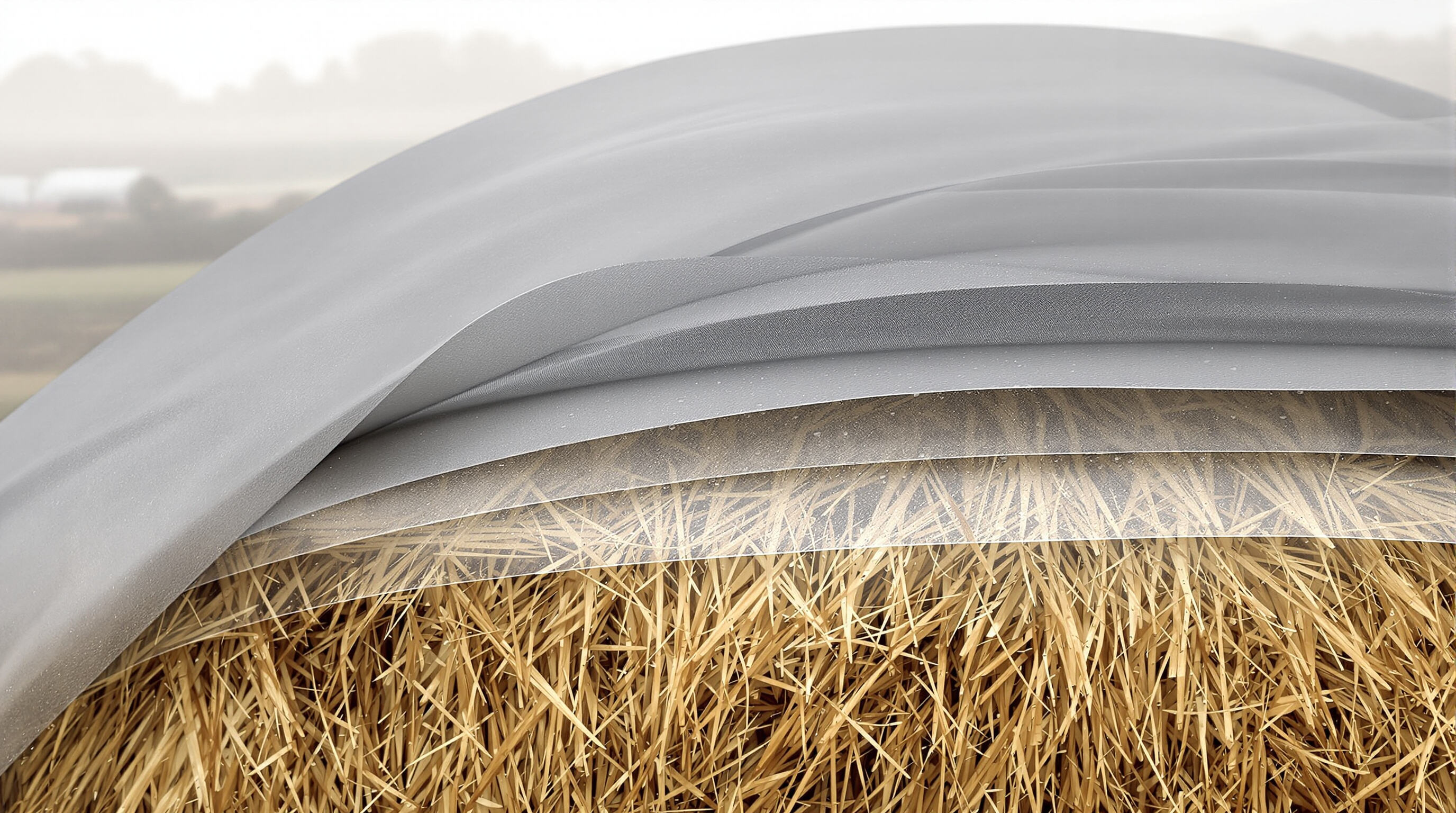

Today's hay covers are built with smart engineering that brings together waterproof protection, UV blocking, and the ability to breathe properly. The outer layer stops rainwater from getting through, but there are tiny pores in the material that let water vapor escape instead of getting trapped inside where it can cause mold growth and even spontaneous heating problems. Studies have shown when hay gets wetter than about 20%, it starts losing valuable nutrients because of fungus growing in there. That's why good quality covers create those important air gaps between each bale and the covering itself, keeping things drier overall.

Why waterproof and breathable covers prevent mold and heating in hay bales

Traditional plastic sheets trap condensation, creating ideal conditions for mold. High-performance covers use capillary-action polymers that repel liquid water while facilitating vapor release. By keeping internal moisture below 18%—a threshold established in agronomy research—these covers inhibit thermophilic bacteria and prevent exothermic reactions that can lead to heating.

The science behind micro-porous membranes in modern hay cover technology

The micro porous membranes work through a clever combination of hydrophilic and hydrophobic layers. The outside basically pushes water away, but inside there are these special layers that actually pull vapor through them. These tiny passageways measure between about 5 to 10 microns wide and let moisture escape at rates over 1500 grams per square meter every 24 hours. That's roughly twenty times better than regular old canvas fabric that hasn't been treated. And for those concerned about sun damage? There's also nano titanium dioxide coating on many of these materials which blocks almost all UV rays. What's interesting is how flexible they stay even when temperatures drop below minus 20 degrees Celsius, making them suitable for extreme weather conditions too.

Industry paradox: balancing moisture prevention with airflow under hay covers

For farmers dealing with outdoor storage, finding the right cover is a constant challenge between keeping rain out and letting air circulate properly. When covers are completely sealed up tight, they tend to trap moisture inside which leads to condensation problems. On the flip side, if the material is too porous, it just lets rainwater seep through instead. The newer generation of covers addresses these issues through smart design features. Some models actually adjust their breathability based on humidity levels inside the storage area. These covers have special sections that open up automatically when moisture builds up from stored crops breathing in the dark, helping maintain dry conditions without completely blocking airflow. This kind of technology makes a real difference for long term crop preservation.

Best Practices for Securing Hay Covers in Harsh Weather Conditions

Best Practices for Anchoring Hay Covers in High-Wind Conditions

To keep those hay covers secure, farmers should use UV resistant ropes or polyester tie downs spaced roughly 3 to 4 feet apart across the top. This creates what folks call a tensioned grid pattern that helps spread out the force from strong winds instead of letting them tear at one spot. Most experienced growers line their hay rows going north to south direction because this matches how most winds blow around here. Some studies done last year actually showed this alignment cut down wind resistance by about 30 percent in real world conditions. Don't forget to leave an extra 2 or 3 feet of covering material hanging off each side of the stack too. This gives room for the bales to shift slightly when loaded or unloaded while still maintaining a good tight seal against moisture getting in.

Use of Straps, Sandbags, and Bungee Systems to Prevent Uplift

When multiple anchoring techniques work together, they really boost performance when dealing with strong winds. Using ratchet straps that cross over stacked items provides extra structural support. Placing sandbags roughly every six feet along the edges helps fight against any lifting forces. For those unpredictable gusts, bungee cords that can stretch about 150% allow covers to move around without ripping, which keeps the downward force pretty steady throughout. A good tip is to make sure overlapping seams are positioned so they face away from where the main wind comes from. This simple adjustment stops water from getting inside and prevents unwanted air movement underneath.

Economic Benefits of Using Quality Hay Covers: Reducing Waste and Maximizing ROI

Tracking annual hay waste and associated costs on mid-sized farms

Mid-sized farms lose 15–35% of their hay harvest annually to weather damage, amounting to $15,000–$30,000 in losses for a 500-bale inventory. In wet climates, uncovered hay can lose up to 50% of dry matter from seepage alone. Major cost drivers include surface spoilage, nutrient loss from heating, and mycotoxin contamination requiring disposal.

Cost-benefit analysis of investing in high-quality hay storage solutions for farms

Premium covers deliver strong returns despite higher initial costs. Over 3–5 years, durable materials pay for themselves through reduced waste:

| Storage Method | Annual Loss Rate | Yearly Cost per 500 Bales |

|---|---|---|

| Unprotected | 20-35% | $19,000-$33,000 |

| Standard Tarp | 10-18% | $9,500-$17,000 |

| UV-Breathable Cover | 5-9% | $4,750-$8,500 |

Proper storage reduces cumulative losses by 60–70%, with most operations reaching break-even within 18 months.

Case study: 40% reduction in spoilage after switching to breathable UV-resistant covers

A 300-acre Wyoming cattle ranch cut discard rates by 40% after replacing polyethylene tarps with triple-layer breathable covers. Mold contamination dropped from three to one event per year, contributing to a 28% decline in herd respiratory illness. The improvement saved $18,000 annually in feed supplementation costs.

Long-term storage improvements and ROI from reduced mold and waste

Covers that let air through while resisting UV damage keep protein content above the critical 14% mark across several growing seasons, which actually meets those NRC standards for beef cattle without needing extra feed additives. Looking at real world results, most farms see somewhere between 12% and 15% return on their money invested in storage solutions over about five years. These returns come mainly from cutting down on wasted product, saving time on maintenance work, and avoiding problems related to harmful mycotoxins that can develop otherwise. When farmers upgrade their covering materials, they're doing more than just protecting their stored forage. It's really about building something that will stand up to whatever challenges come along in the future of their operations.

Frequently Asked Questions (FAQ)

Why are hay covers important for forage quality?

Hay covers help protect forage from rain, snow, and UV damage, preserving its dry matter and crude protein content.

What materials are commonly used for hay covers?

Common materials for hay covers include polyethylene tarps, UV-resistant plastic, and treated canvas.

How do hay covers prevent mold and heating in bales?

High-performance covers use capillary-action polymers that facilitate vapor release, keeping moisture below harmful levels.

What are the economic benefits of using quality hay covers?

Quality hay covers reduce waste and contribute to a significant return on investment by maximizing forage preservation.

Table of Contents

- Why Hay Covers Are Essential for Preserving Forage Quality

- Comparing Hay Cover Materials: Tarp, Plastic, and Canvas Options

- Key Features of High-Performance Hay Covers: Waterproof, UV-Resistant, and Breathable

- Best Practices for Securing Hay Covers in Harsh Weather Conditions

-

Economic Benefits of Using Quality Hay Covers: Reducing Waste and Maximizing ROI

- Tracking annual hay waste and associated costs on mid-sized farms

- Cost-benefit analysis of investing in high-quality hay storage solutions for farms

- Case study: 40% reduction in spoilage after switching to breathable UV-resistant covers

- Long-term storage improvements and ROI from reduced mold and waste

- Frequently Asked Questions (FAQ)